4 Side Seal – FDCP

4 Side Seal – FDCP – for Liquids & Semi Liquids

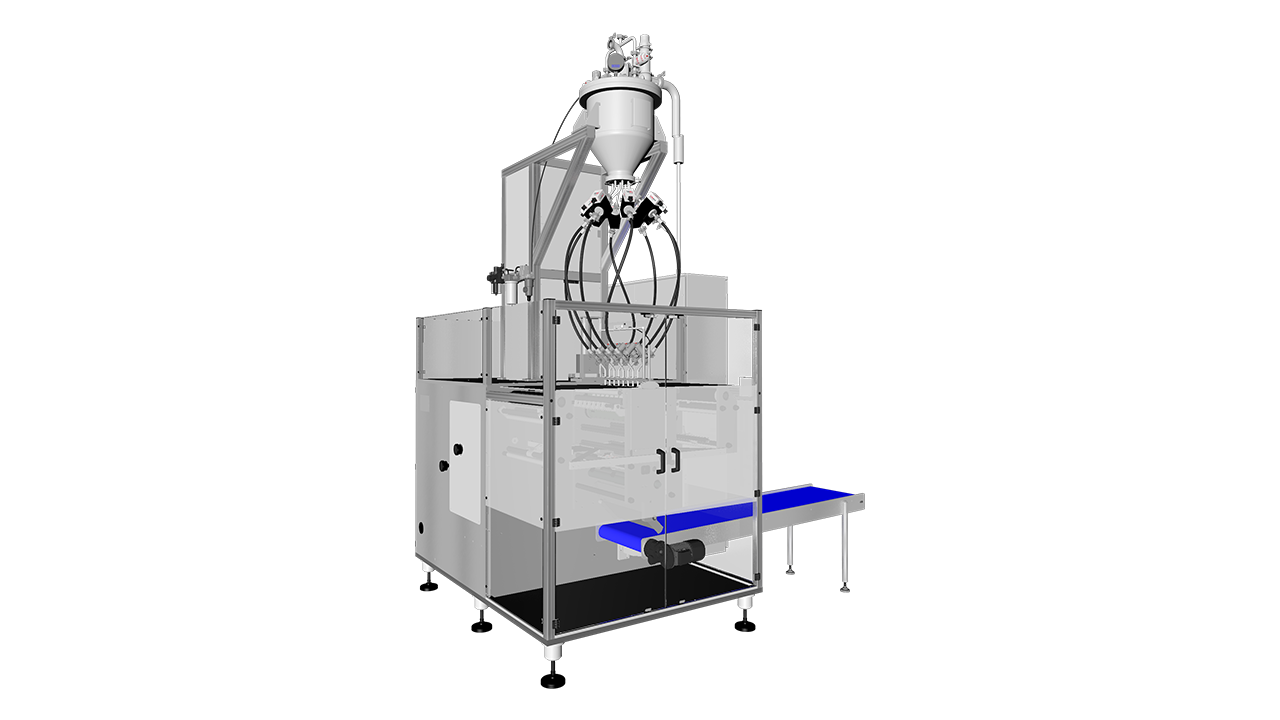

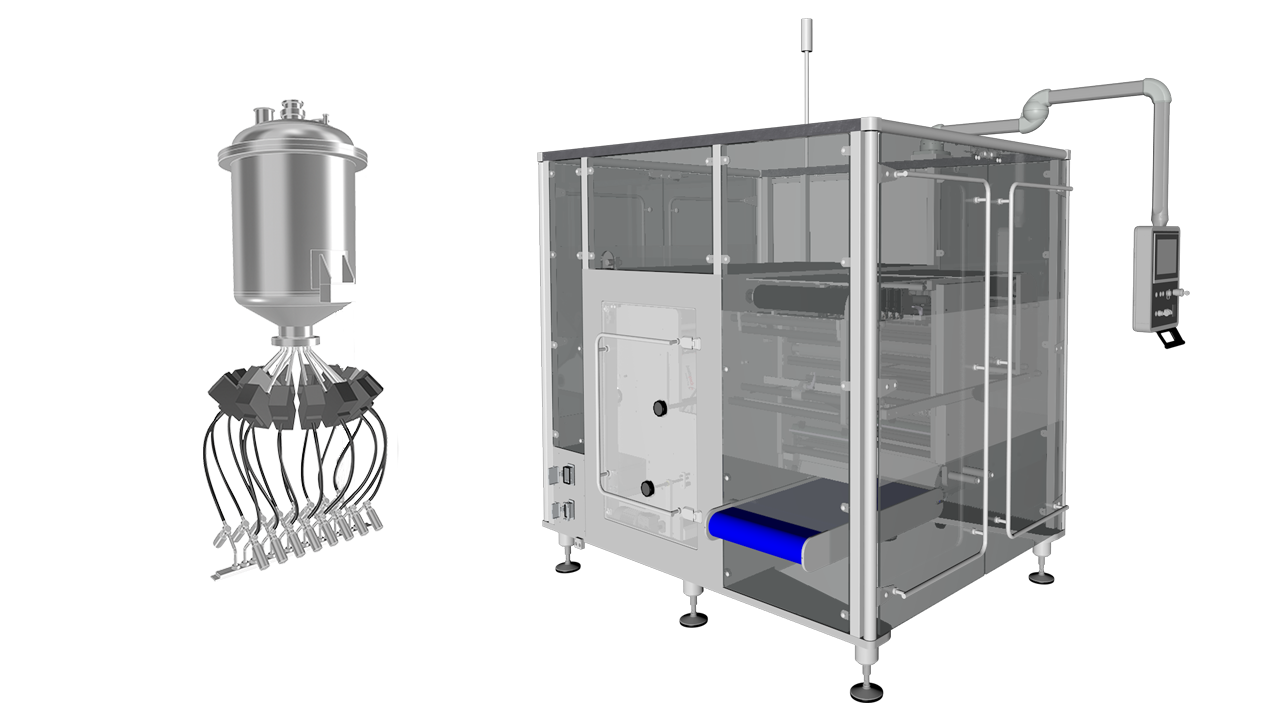

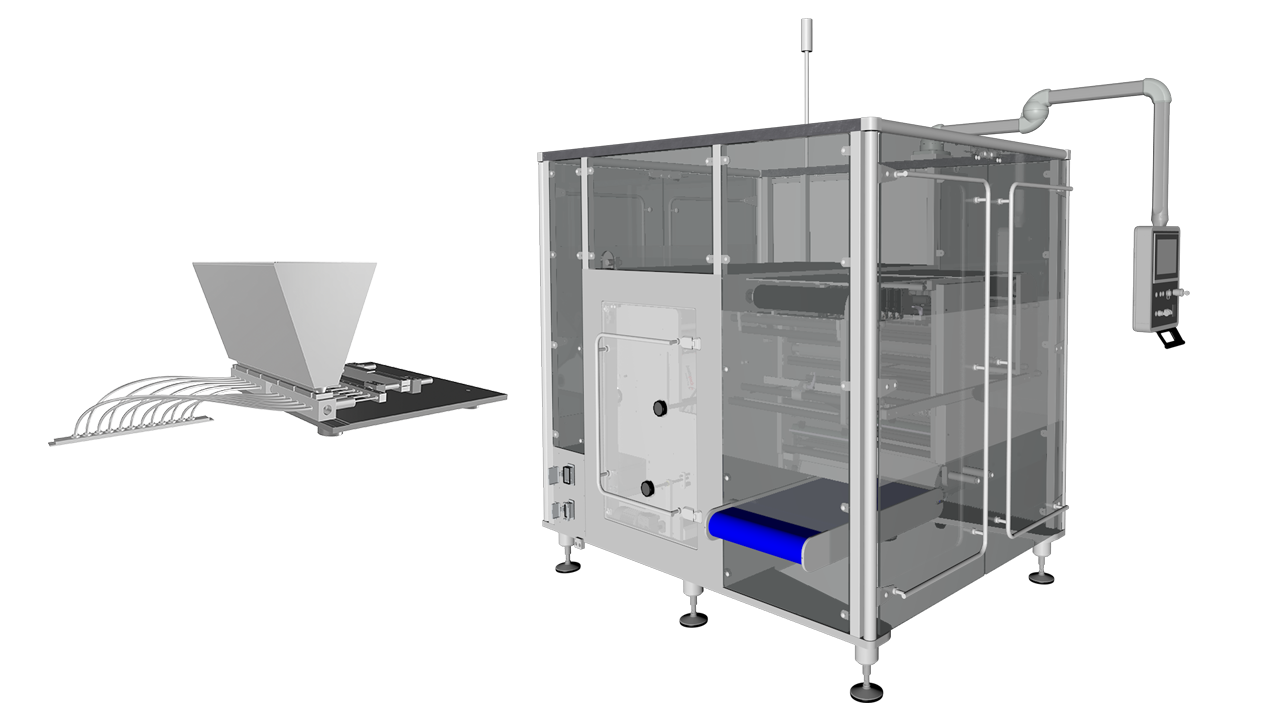

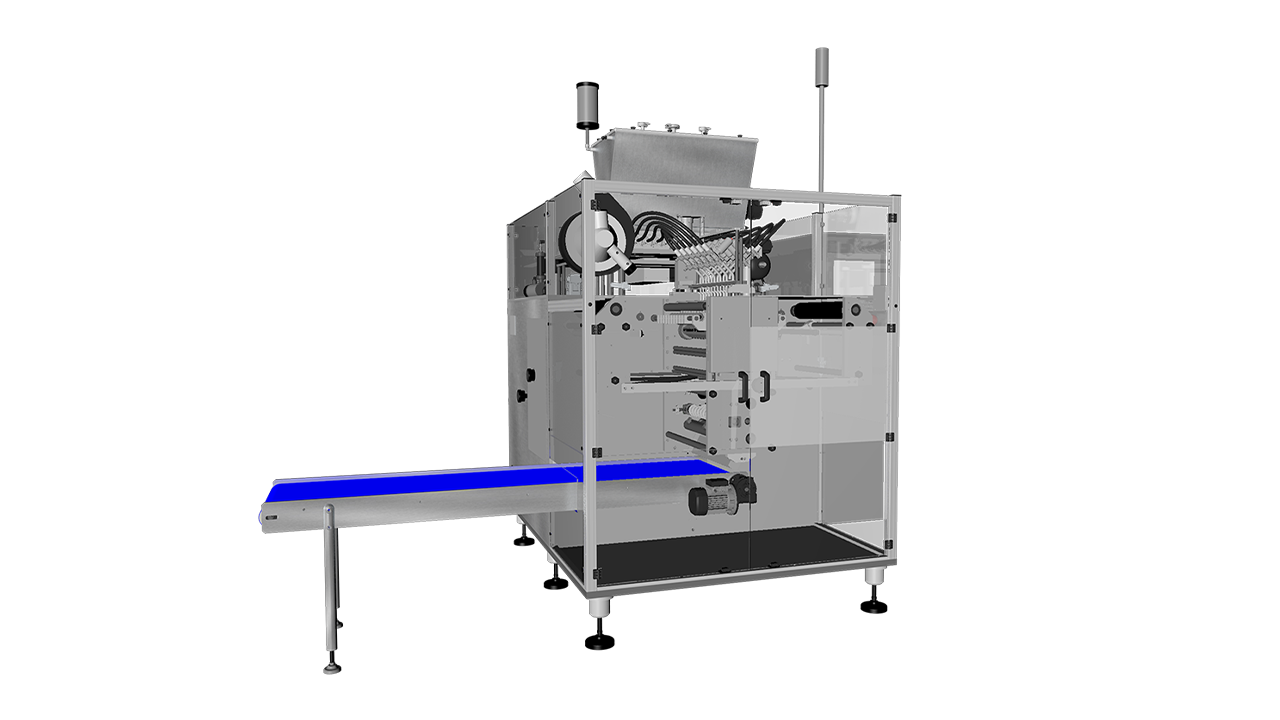

Doser for liquids or semi-liquids (ketchup, mayonnaise, mustard, etc) with pumping syringes and rotating cylinder.

- Volumetric feeder suitable for semidense liquids that might contain small particles.

- Complete with hopper, hopper lid and suitable injection nozzles for the product to dose.

- Servomotor driven doser to allow high speed and very precise control of product flow.

- All the parts in contact with the product are made of stainless steel or other food grade material.

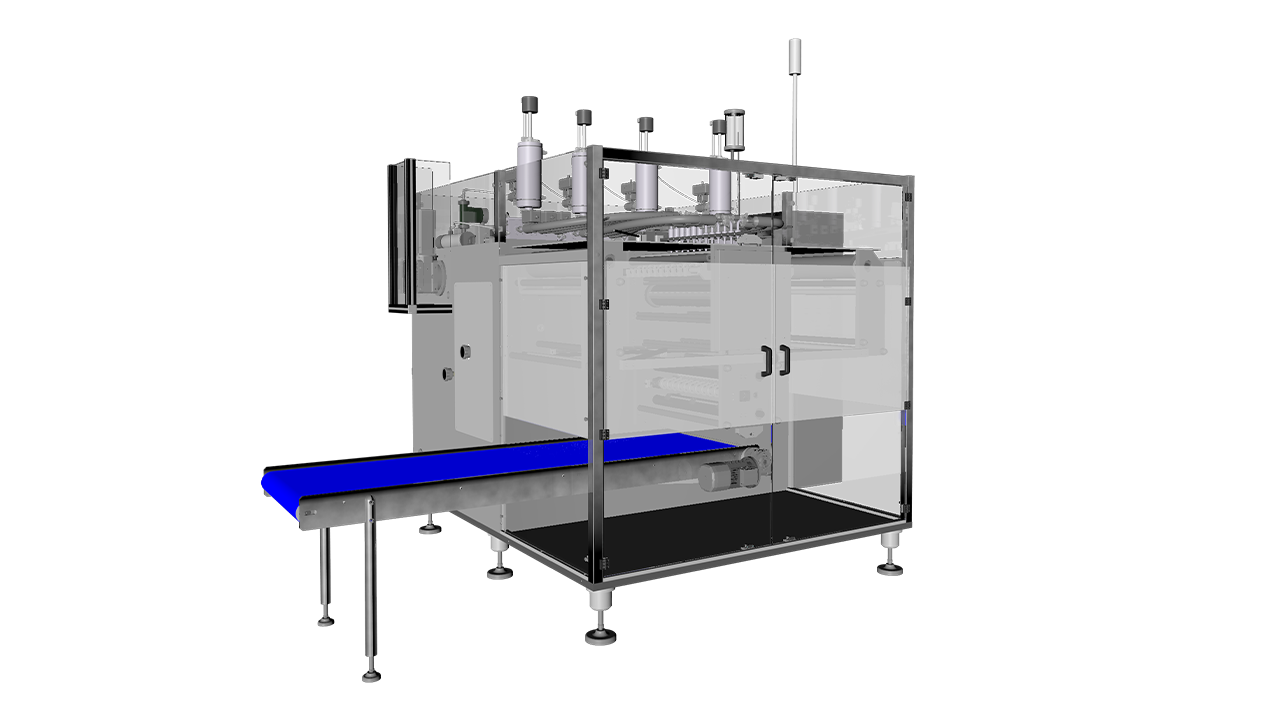

- reels up to 1200 mm width [sealing width up to 600 mm] and 600 mm diameter;

- various servo-driven dosing systems available for wide range of products such as: liquids, powders, wet tissues, tablets, small solids;

- BPMBS®: patented modular construction system for rapid maintenance and easy sachet format change;

- standard device:

- automatic and motorized reel unwinding;

- automatic print registration [patent pending];

- modem for remote troubleshooting and PLC software status diagnosis;

- basic parameters easily adjustable from control panel [sachet length, output speed, number of sachets to form a group, sealing temperatures, enabling and/or timing for various devices eg. hopper agitator, photocell control, printer, vibrator, etc.];

- various optionals available such as:

- automatic reel centering;

- reel join detection;

- easy tear notch;

- transversal and/or longitudinal perforation devices;

- dosing system accessories;

- end of line systems [automatic cartoning machine, manual cartoning conveyor, etc].

- 10” touchscreen operator panel;

- recipe management: all settings [including phasing of knives] can be saved and retrieved for fast setup during format changes;

- machine logs access from LAN for statistic purpose;

- flexible remote access for assistance and upgrades. N° 3 [three] connection modes can be used to connect the machine.: local network connected to internet, phone connection to a local internet provider, direct phone connection;

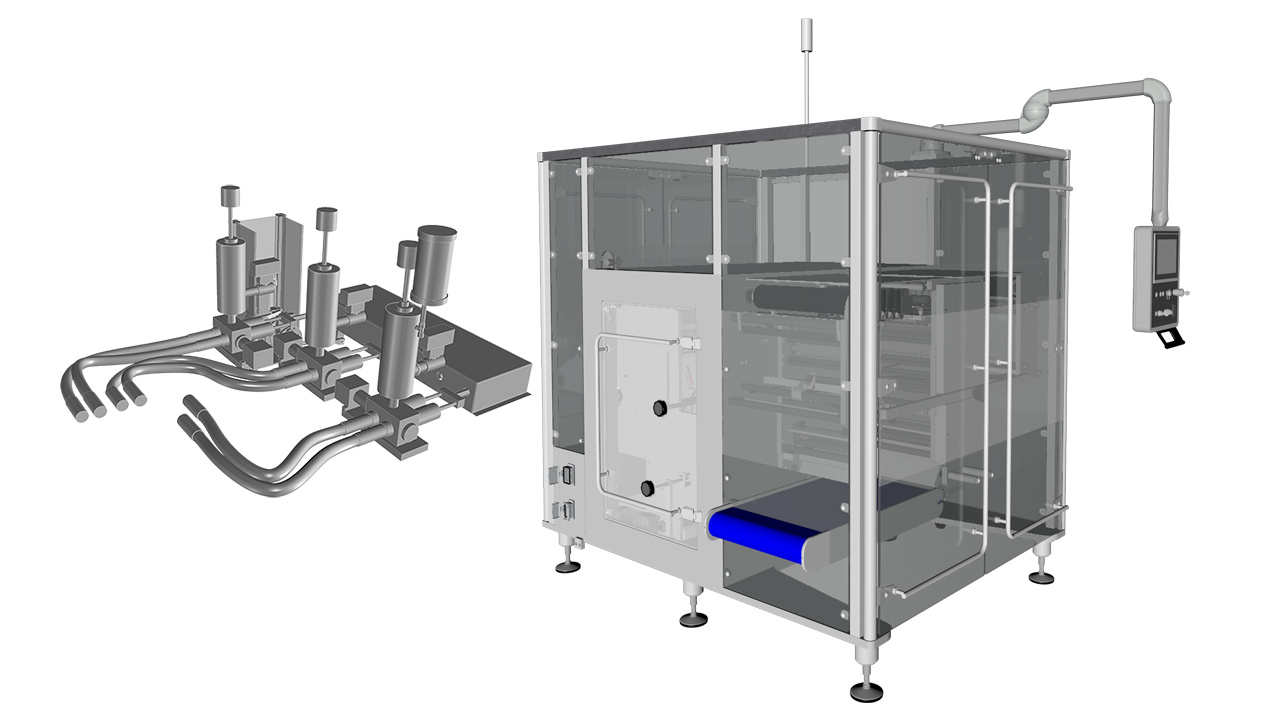

- N° 5 [five] brushless motors: FILM, JAWS, DOSER, TRANSVERSAL CUTTING KNIFE, TRANSVERSAL STRIP KNIFE;

- optional brushless motor fo PRINTER head movement;

- sealing jaws electronic alternation system;

- N° 2 [two] separate motorized knives for transversal cut and perforation function. The phase of each knife can be set from the operator panel without stopping the machine;

- cooled electrical cabinet;

- improvement of PILZ safety system by utilization of magnetic safety switches on the doors and a dedicated safety module for axes speed control.

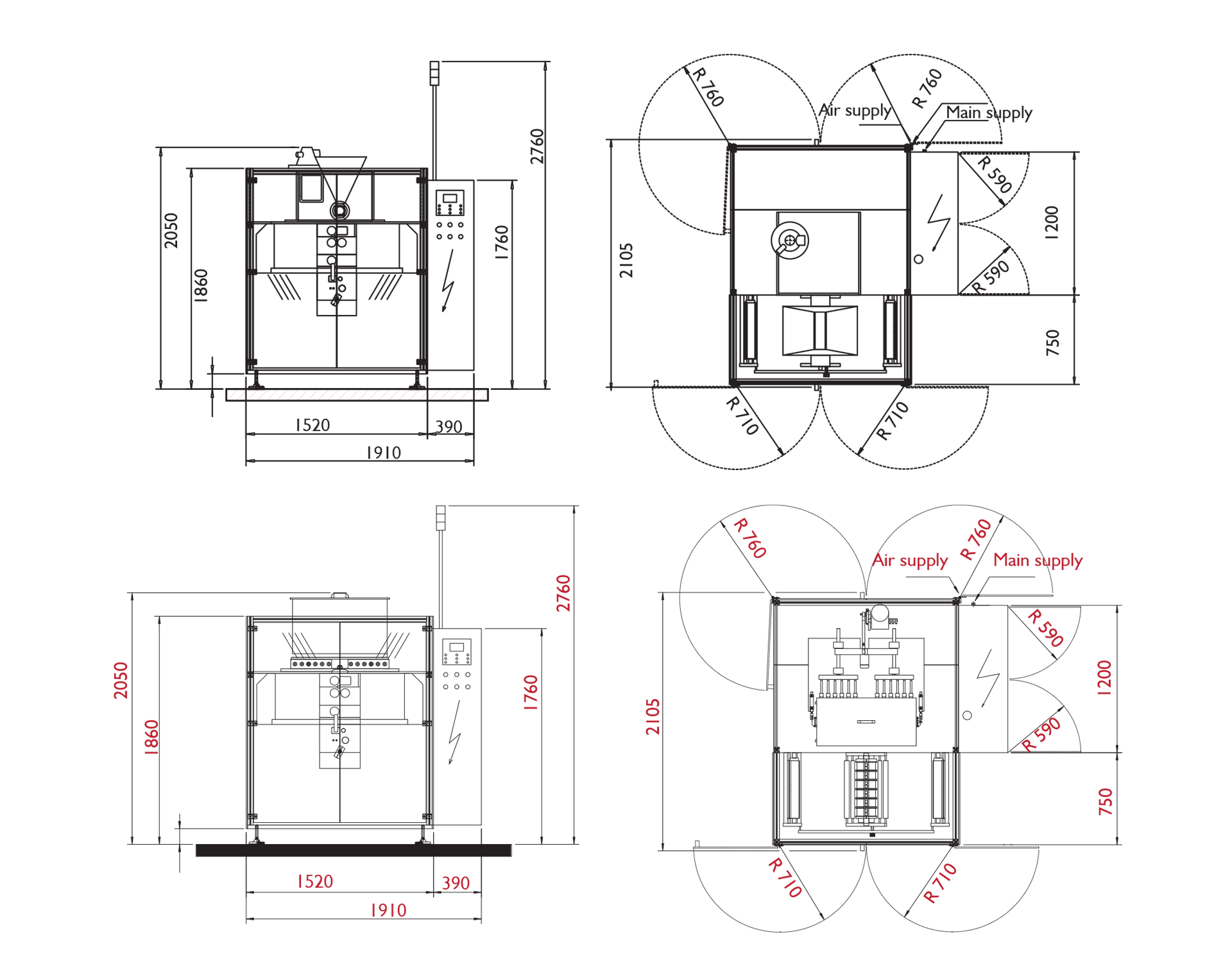

| max reel width | 600 / 900 – 960 / 1200 mm (reel width / 2 / sachet width = n° production lanes) |

| max reel diameter | 600 mm |

| sachet width | min. 25 / 40 mm – max. 150 mm |

| max sachet length | 250 mm |

| voltage | 400 V + N + PE |

| installed power | 20 Kw |

| average absorption | 3 – 4 Kw |

| output speed | in excess of 4000 sachets/min. |

| dimensions [max] | 2800 x 2260 x 2210 mm |

Packaging solutions for liquids, powders, solids and wet tissues